Did You Expect It Would Take This Long To Go Public?

By Rob Wright, Chief Editor, Life Science Leader

Follow Me On Twitter @RfwrightLSL

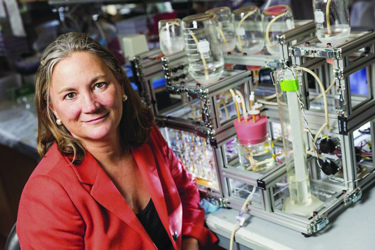

Nearing the end of an interview with Laura Niklason, M.D., Ph.D., CEO of Humacyte, a regenerative medicines company she cofounded in 2004 (subject of an upcoming feature in Life Science Leader), I posed the question, “Did you expect it would take this long?” This was in reference to how long it took for Humacyte to go public, as we had just finished up a conversation on the company’s plans to do so via a special purpose acquisition company (SPAC) this year. “No. It has taken about twice as long as I thought it would,” Niklason admits. “We’re a 16-year-old overnight success.” But the CEO doesn’t believe those previous 15 years were wasted. “It gave us time to build a very dedicated team and a completely integrated company, so we are better able to control our own destiny.” To understand why this integration was so important, consider what it is they are trying to do. The company uses cells to make bioengineered human tissue, which is regulated as a biologic by the FDA. A decellularization process makes these tissues universally implantable. Decellularization can best be described as a process to remove the donor identity from the human acellular vessels (HAVs) by washing away the cells and DNA (which could spark an immune response) from the newly grown tissues. Protein components left behind that make up the HAV are able to be implanted into any patient without the need for matching or testing, and no risk of rejection, rendering the HAVs universally implantable. The tissues are capable of being manufactured at commercial scale, and because they are not living, have a shelf life of 18 months. After implantation, using needle and thread surgical procedures, these tissues become repopulated with cells from the patient. “Because we make our own product and do our own testing, we’ve been able to better manage risk.” At one point the company did partner its manufacturing with a corporate partner, but the decision was made to bring that expertise back in-house. “We think that gives us the most reliable manufacturing output and the ability to quickly troubleshoot and innovate to make things better.” However, there is so much more to this story. For example, after the company was founded, Niklason, though very active in the company, remained working fulltime as a professor at Yale University. So, be sure you don’t miss out on learning all about this professor-turned-entrepreneur by becoming a Life Science Leader subscriber today.