How To Achieve Excellence In A Biopharma Supply Chain

By Rob Wright, Chief Editor, Life Science Leader

Follow Me On Twitter @RfwrightLSL

When Walt Kelly put the quote “WE HAVE MET THE ENEMY AND HE IS US” on the first Earth Day poster in 1970, it is doubtful he envisioned it applying to the biopharmaceutical industry. Yet, for David Lowndes, SVP of supply chain management at Shire Pharmaceuticals, the quote is pertinent to how his company approaches working with supply chain partners. He says it all started with a paradigm shift related to how Shire maintained the integrity of supply for its wholly outsourced, 100 percent virtual small molecule drug business. “We had seen the Heparin disaster of 2008, and I think we [as an industry] all knew there was a huge gap in our supply chain capabilities,” Lowndes shares. “In 2012, Xavier [University, through its PharmaLink conference] initiated the integrity of supply initiative, with the idea being to increase product confidence.”

When Walt Kelly put the quote “WE HAVE MET THE ENEMY AND HE IS US” on the first Earth Day poster in 1970, it is doubtful he envisioned it applying to the biopharmaceutical industry. Yet, for David Lowndes, SVP of supply chain management at Shire Pharmaceuticals, the quote is pertinent to how his company approaches working with supply chain partners. He says it all started with a paradigm shift related to how Shire maintained the integrity of supply for its wholly outsourced, 100 percent virtual small molecule drug business. “We had seen the Heparin disaster of 2008, and I think we [as an industry] all knew there was a huge gap in our supply chain capabilities,” Lowndes shares. “In 2012, Xavier [University, through its PharmaLink conference] initiated the integrity of supply initiative, with the idea being to increase product confidence.”

The 42-member team working on that initiative represented a wide variety of industry stakeholders (e.g., pharmaceutical, biotech, food, medical device, suppliers, regulatory, and academia), and the team embarked on a structured research process (e.g., gap, cause and effect matrix, and Pareto methods of analyses) to tackle the problem. “The data came back saying we should really be looking more at ourselves than our suppliers,” Lowndes concedes. “Supplier surveys and focus group sessions corroborated those findings.” What emerged were three key areas that biopharmaceutical companies (i.e., customers of suppliers) needed to focus on. “Those three areas were our understanding of our products and processes, our supply chain management capabilities, and finally our behaviors within that system,” he states. When faced with the reality that the enemy of supply chain integrity was most often the customer, Shire embraced the opportunity to become a better customer. In that same spirit, Lowndes invited two members of Shire’s supply chain network to share their insights on what biopharmaceutical companies can do to be better customers, and consequently achieve better supply chain integrity.

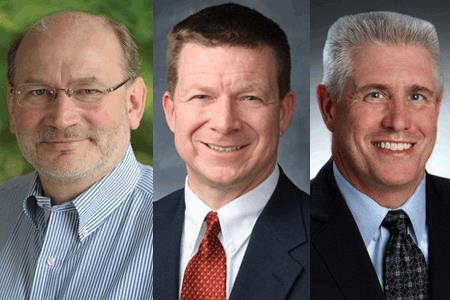

Andy Polywacz, VP, quality & regulatory affairs at West Pharmaceutical Services, Inc., and Harry Gill, SVP of quality and continuous improvement at Patheon, have a combined 55 years of industry quality and plant operations experience that include stints at Baxter, Catalent, Cardinal Health, and Wyeth (now Pfizer). “These two have a multitude of customer relationships and, therefore, a very broad set of experiences to draw on,” Lowndes states.

What Six Issues Impede The Building Of Strategic Partnerships With Suppliers?

Issue No. 1

ALIGNED SPECIFICATIONS — ALIGNED EXPECTATIONS

ANDY POLYWACZ: The first issue that jumps to mind is a misalignment of expectations between the supplier and the customer. In my experience, we typically come to alignment on specifications fairly quickly. But a specification is just the start. Where we often end up getting tripped up is with the expectation. For example, let’s say West is working with your company’s supplier quality group regarding stoppers going into your facility. You tell us this is the stopper specification you need, and we all sign our agreement. However, what if this doesn’t align with what you need at the end of your fill line? All of a sudden we’ve got this disconnect and can’t release a drug product lot. Despite the “spec” having made it through your incoming quality checks, and West having not done anything wrong, we still end up interrupting the supply chain, and patients aren’t getting their drugs. That’s a big problem and an example of misalignment of an expectation.

Where we are trying to be more collaborative with our customers is beginning the conversation by asking, “What do you need this to do? Let’s talk about what the drug is. What is the delivery method? How is it getting to the patient? How is the patient going to use it?” From there we can walk back through the supply chain and look at things like the types of filling systems you already have. Do you have vision inspection? As we keep walking backward, we can now build a specification that meets the expectations of the supply chain, not just getting it past incoming quality. While those conversations have a lot of value, they require taking more time up front. However, the value those conversations have on the overall integrity of your overall supply chain pays off exponentially.

Issue No. 2

DOES SUCCESSFUL TECH TRANSFER = PRODUCT AND PROCESS ROBUSTNESS?

HARRY GILL: One of the issues we identified is a lack of product and process robustness after the development or tech transfer is complete. Let’s say we go through everything and it looks really good. But when we go into production, we start to see deviations. The No. 1 issue that causes us, as a CMO, to miss on our on-time delivery is process deviations. As a client you are understandably upset when a CMO is late on delivery because you can bet that this type of situation usually happens when your demand for your product is going up in the market. What do you think about when trying to mitigate stability problems or deviations that lead to the need to file field alerts or taking regulatory agency actions? As your CMO, the first thing we want to be able to turn to is your product’s chemistry, manufacturing, and control (CMC) section and development reports, inclusive of all the things you’ve done to create your design space.

You would think this is common sense, right? After all, you want us to make something for you. As such, you would think that giving us the rules that you filed with the agency would be useful in order to make it correctly. Two years ago we had a PAI [pre-approval inspection] in one of our European facilities. About two days into the inspection the investigator asked us if they could see our packaging validation and visit the packaging line. We were a little stunned. Why? Because we thought we were just going to provide bulk drug tablets for packaging later by someone else in the client’s network. But because the client had put us in the dossier as a packager for this particular product, we ended up getting a 483 [a notice of the need for corrective action], the PAI failed, and the client ended up taking us out of the dossier completely. The end result was both sides lost (i.e., they lost their U.S. market risk mitigation strategy, and we lost a business opportunity for which we had actually set up capacity just to manufacture that product). During a more recent negotiation, a client balked at our quality agreement because it stated that they had to give us their CMC section. They were concerned with protecting IP, stating that the IP was in the API, and since all we were doing was putting it into an oral-solid dose in a traditional solid-dose manufacturing process, we didn’t need the CMC. Eventually the client capitulated, signed the deal, and everybody was happy. But it shouldn’t get to the point where we feel like we are forcing you to give us the information necessary to successfully make your product.

Besides, if manufacturing in Europe, even if not for EU distribution, the Medicines & Healthcare products Regulatory Agency’s (MHRA) Annex 16 specifies that a medicinal manufacturing facility is required to be certified by a Qualified Person (QP) against the CMC. Similarly, FDA guidance also specifies that the customer has to share the CMC section with their CMO.

Issue No. 3

HOW MUCH TRANSPARENCY DO YOU REALLY WANT?

POLYWACZ: We talk about transparency in many different ways. For example, transparency from a raw materials standpoint could be what happens when we need to make a raw material change. In the supplier- customer relationship we need to agree on what transparency specifically means. It may sound like a silly question of what it means to define transparency, but the reality is that transparency has a lot of different legs. One thing customers need to consider is that when your supplier is transparent and shares information with you, please appreciate that trust. The agreement as to what levels of transparency are going to be in place between supply chain partners goes both ways. For example, when we ask, “Where is this drug product going to be marketed?” and you say, “We can’t tell you that,” you’ve greatly hindered our ability to help you. Let’s say you are trying to get a drug product into Japan, but it’s getting bounced out for a particulate. If we had that conversation up front we could have built in the appropriate “spec” for entry into that particular market. Unless you agree on the level of transparency up front, communication will often end up with a lot of back and forth and with more angst around issues when they arise. If you want your supplier to be transparent, you as the customer should consider reciprocal transparency.

Issue No. 4

WHAT IS THE IMPACT OF A MISSED FORECAST?

GILL: Another customer issue involves client forecasting, in particular for new product launches. Here is an interesting statistic. During DCAT Week 2016, results from research conducted by ORC International were published as a white paper. ORC interviewed 50 pharmaceutical company executives and found that 65 percent of all product launches miss forecasts by more than 25 percent, either high or low. Now, this is pretty logical. As a manufacturer, when you’re trying to decide what your supply chain will look like for a new product, you have to make decisions three to four years ahead of time. And while we can joke that the one thing that will be right with every forecast is that it will be wrong, customers need to consider the impact of a missed forecast. When you miss by forecasting too high, that’s an impact to our business because as a CMO we may have been counting on that particular volume. When you miss low, that impacts the patient.

Recovering from a missed forecast of 30 to 50 percent can be very difficult. However, we’ve had a client miss a forecast on the low side by 500 percent. When you haven’t planned for this type of demand, it becomes very difficult for your CMO to react in order to supply, in some cases, lifesaving drugs. To try to mitigate that risk we do our own market research. Even if it’s an orphan drug, we will identify the population for that particular disease. If it is a new drug that is being released, we’ll look at the market for similar products and work with customers to develop some risk-mitigation strategies (i.e., suggest they consider doing an alternative train in the same facility, an alternate site, either in or outside of our supply chain). Everybody knows that forecasting of new products can be difficult. However, we should be much better at the forecasting of established products. Many forecasts have variability within the first three to six months and then flatline. If a CMO has to change capacity to meet increased volume needs, unless they are sitting on idle capacity, it can be very difficult for them to help. We work best when integrated into the client’s S&OP [sales and operations planning] process and can see all the markets they are in. If we know where a client’s supply is in every single market, we can work together to help mitigate issues when forecasts are missed.

Issue No. 5

HOW DO YOU ENGAGE WITH SUPPLIERS WHEN THINGS GO WRONG?

POLYWACZ: The fifth issue I will refer to as the lack of rules of engagement. I’m not just talking about a quality agreement, which can be great unless it is just a battle of templates (i.e., “I need a quality agreement.” “OK, here’s our template.” “No, we can’t use yours, so here is ours.”). What does defining rules of engagement really look like in realworld collaborations? Simple, define and resolve issues when something goes wrong (and trust me something is always going to happen). Don’t just keep escalating the issue because often all that does is bring things to a head. What we want to try to do is resolve issues proactively. Neither of us wants to have an issue that puts us at a standstill. So how can we prevent such situations?

One solution can be to have a third party empowered to make a ruling on issues, and we have agreed that we are willing to live with whatever the third party decides, whether it be a testing lab or another entity. In a strategic partnership there should be “noisy” dialogue. Because if we are heading to a point where we are seeking to protect our own mutual interests, we aren’t going to find the solution by throwing our quality agreement forms at one another. Think about building rules of engagement into a quality agreement so that the quality agreements actually work. If you have had the conversations you need to have on how you want to deal with issues when they do arise, you already know how to go about resolving those issues.

Issue No. 6

STRATEGIC PARTNERSHIPS CAN’T BE DONE TRANSACTIONALLY

GILL: What is the relationship you have with your CDMO (contract development and manufacturing organization)? We probably don’t have a single client that doesn’t want to be our strategic partner. However, like any good relationship, a strategic partnership requires work. The term strategic partner can sound really good when spoken in the higher echelons of an organization. However, when you get down in the trenches and the procurement teams get involved, that’s where you tend to get into a transactional relationship. Problems that arise in transactional relationships tend to be much more difficult to solve. If you’re in a problem-solving mode and one of the parties starts quoting the quality or manufacturing services agreement, it is much less likely that any problem resolution is going to end up satisfactory for anyone. Once the focus becomes “what is” and “is not” in the documents, you’re done because at that point you are no longer solving problems but trying to mitigate your own risk.

To prevent these situations from occurring, you need robust governance models, and these require a great deal of time to construct collaboratively. Governance models work best when they work where the work is being done (i.e., the sites) and among the people working most closely together. The people at these levels should be able and empowered to solve 90 percent or more of the problems. Having the customer put a person directly in a plant also can help with creating strategic partnerships. As a matter of fact, if we follow some rules of engagement, it actually is better for us because we have somebody we can talk to every day about any issue. Clear escalation process models of who to talk to next when problems can’t be solved at a particular level are helpful. Quarterly or semiannual face-to-face meetings between the right people who can talk about the strategic relationship is another consideration. When you try these approaches you are much more likely to have success because the reality is — it’s always easier to have a relationship with somebody if you can look them in the eye versus trading emails.