How To Qualify A CMO's Capabilities And Benchmark Its Performance

By Ed Miseta, Chief Editor, Clinical Leader

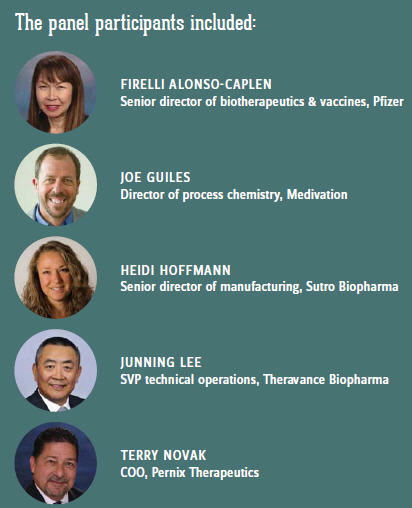

Choose the wrong CMO and your project could easily be derailed, costing your company billions. But how do you avoid making such a mistake? To help answer that question, Life Science Leader brought together a panel of outsourcing experts at the inaugural Outsourced Pharma West conference and exhibition in San Francisco last November. Our panelists share some personal experiences and lessons learned on the topic.

WHAT ARE SOME CHALLENGES TO FINDING A PARTNER THAT ALIGNS WITH YOUR NEEDS?

Terry Novak, Pernix Therapeutics: When you ask that question, you will always hear people saying the same things… capabilities, quality, and regulatory. And all of those factors are important. But I believe sponsors need to take a very detailed approach to these partnerships, much like performing due diligence when acquiring a new product. I like to look at quality, regulatory, and delivery history, but I ask a lot of other questions as well. What is their turnover rate? How long has the management team been in place? Are they able to scale up? If they can’t, am I going to have to pay for the capital? These are all questions that should be addressed up front. I was always big on case studies and whether they had worked on a project like mine and were able to deliver. Be as detailed as you possibly can be and always make your expectations very clear from day one.

Heidi Hoffmann, Sutro Biopharma: I recommend that every sponsor take some time right up front to determine what their business model is and how far they want to take the project. It’s important to delve down into the details and understand the strengths of your company. Only then can you try to identify a CMO that complements those capabilities and has expertise that you lack.

This will allow you to prepare a business plan and determine what capabilities you intend to develop over the course of a project versus what you would prefer to outsource and not commit resources to having in-house. Understanding that will make the CMO selection process much easier.

Joe Guiles, Medivation: One point that Terry mentioned really resonates with me: The people involved in the process are critical. If you are the customer, you have to have access to the best people you can get at your CMO.

Turnover is important because you need to have an understanding of their stability. In the end, it’s the people working for that CMO who will deliver the product you need. Most service providers have the same technologies in-house. The people who operate those technologies will be the difference makers.

Finally I would just add a short comment about the RFP process. Companies that do not put a lot of time and thought into their RFP will end up in most cases not getting what they want in a response. I think there are different strategies on how to approach it. I believe you need to put enough information in the RFP to get your responders to think and hopefully open a dialogue with you. How CMOs behave in the RFP process is often a mirror of how they will behave under contract. Are they alert, attentive, on-time, thinkers/ problem-solvers, during the RFP process?

Firelli Alonso-Caplen, Pfizer: At Pfizer, we do not believe cost should be the major driver when selecting a CMO. That may surprise some people, but what’s more important to us in pre-commercial outsourcing is getting the quality and timeliness we desire. The time schedule we have set for getting the drug to the clinic has to be reached, and therefore we need a CMO that can meet our schedule. Cost has to be taken into consideration, but it is never the most important consideration.

Terry Novak

In a recent outsourcing decision I was involved in, we started off with a list of five CMOs and then started narrowing it down. One CMO was being taken over by another company. It was eliminated because we didn’t know whether it would still be in existence at the end of the project. Another CMO was eliminated because it had no prior experience with the FDA.

Experience was a factor we looked at very closely, and the CMO we ultimately selected was one that had a pre-approval inspection waived by the FDA earlier in the year. That CMO was more expensive than the others, but the FDA decision resulted in a huge savings for us, which made the decision to go with them much easier. That CMO ended up having a waived PAI for our project as well.

WHAT ARE SOME OF THE PROS AND CONS WHEN ENTERING A RELATIONSHIP THAT IS STRATEGIC VERSUS TACTICAL?

Novak: I have spent 13 years in this industry leading three different CMOs. I have found that a majority of the customers I worked with will often talk strategically then act tactically. Unfortunately you don’t find that out until you get to the Master Service Agreement (MSA). They initially talk to you like a partner but then include how they will hammer you with penalties if something goes wrong. That is not strategic.

Customers that truly want a strategic relationship will sit down with you at the start of the process and say, “Here are our expectations. How can we work together as a team to make sure we accomplish these goals?”

I have always felt that if you’re working with a CMO, you’re in it for the long haul, unless they really mess up because the cost of getting out of a relationship can be tremendous. But it is still important to define that relationship right up front, and to be honest about it. I currently work with 23 CMOs, and I would only classify one of them as being truly strategic.

Guiles: Terry makes a good point. When entering into a strategic relationship, keep asking yourself if this company is the long-term partner you had expected.

Alonso-Caplen: I would define a tactical relationship as one where you need additional drug product produced but have run out of available capacity. To me, a true strategic sourcing relationship has to be one where the companies are truly partners. That means you share in the risk, and you share in the success. And you don’t start blaming each other when something goes wrong.

MANAGING THE OUTSOURCING RELATIONSHIP IS MUCH DIFFERENT FOR A SMALL COMPANY THAN A LARGE ONE. IF YOU ARE NOT A LARGE COMPANY, HOW CAN YOU MAKE SURE YOU ARE STILL GETTING THE MOST OUT OF YOUR CMO?

Junning Lee, Theravance Biopharma: When I first joined Theravance, the company had only one product, but it was a difficult molecule. We had a medicinal chemist who was running all of the CMC (chemistry, manufacturing, and controls). At that time it would have been very difficult to select a CMO. They would have needed a knowledge of chromatography and how to handle an unstable and volatile product. We also had very low yields.

As we moved more product into the pipeline, we gradually built an internal CMC capability. We created several ACE (Analytical Chemist Engineer) Quality Teams that worked together to review processes and activity at various stages. They reviewed assays, ID mapping, studies of different phases, the relevant documents that needed to be submitted, and what experiments had to be run to get the data we needed. We needed a good understanding of the process.

Firelli Alonso-Caplen

The ACE QT developed the process, and eventually we were able to demonstrate it in the laboratory post-Phase 2. Only when we were able to move to late stage did we consider transferring it to a CMO. We have since produced 59 commercial batches without a single deviation and even gotten a pre-approval inspection from the FDA.

So long story short I think you really need to understand your technology before you can even consider working with a CMO. We now have 13 clinical products and one commercial.

Novak: I think there are a lot of smaller companies that feel they are not getting the attention they deserve from their CMO. If you are a small company, here is the best piece of advice I can give you: Develop an internal champion at your CMO, and make sure that person knows your company as well as you do.

If they know your company inside and out, they will be representing you in that CMO. The good ones will do that very, very well, but they need that knowledge from you to know what your company is all about.

Guiles: One of the things that has served me extremely well is former colleagues who are now located around the world, both as customers or in CMOs. These are folks whose quality of work and technical skill you understand and whose opinions you can trust based on how well you know them. I recommend leveraging social media tools, like LinkedIn, as a means to get in touch and have conversations with them about their experiences with CMOs they may have used or are currently using.

ONCE YOU HAVE AN INTERNAL CHAMPION IN PLACE AT THE CMO, HOW DO YOU MANAGE THE RISK OF THAT PERSON LEAVING, BEING REPLACED, OR GETTING OVERBURDENED?

Alonso-Caplen: I believe project management is key to the success or failure of your contract. The folks running the processes are certainly important as well, but having an efficient project manager is critical.

At some point, a project manager you are working with is going to leave, so it’s important to look at how deep the bench is. Ask that person if they were to leave, who the likely replacement would be. Get to know that person, too, if you can. One of the parameters I look for in a CMO is that project management capability. One small CMO we looked at years ago asked, "What is project management?" That should definitely send up a red flag.

Junning Lee

Hoffmann: I completely agree with those comments. A good project manager is vital. I would add that if you are not happy with a project manager, don’t be afraid to ask for a change. Go to the sales department or the person you originally contracted with and tell them it’s not working and that you need someone new. If you are an unhappy customer, someone there will want to make you happy.

Alonso-Caplen: I like to compare the CMO/client relationship to a marriage. The RFP process is the courtship where both companies present their best sides. This will lead to a contract being put in place, which is the marriage. Then you go through the tech transfer process and production, which could lead to many happy anniversaries or an unhappy divorce.

As in other relationships, if there is a break, it usually occurs in the communications process. I cannot overemphasize the importance of communication. It is always better to over-communicate than to under-communicate, and having that project manager be the center of communications between the CMO and the client will help the process.

HOW CAN YOU BALANCE THE DESIRE TO PICK A TRUSTED PARTNER VERSUS THE NEED TO SELECT THE BEST CMO FOR YOUR CURRENT STAGE OF DEVELOPMENT?

Lee: Both factors are very important. I think selecting the right CMO is a must in the first phase. Once you have the right CMO on board, you can start building the relationship. The principles I tend to focus on are capacity, capability, compliance, communication, and creativity.

We had a very good experience with a European CMO. We were working on a product with low yields and impurity issues. We had to scale up and had to move very quickly. It was a challenging project.

We selected the CMO we felt was the best fit and had their chemists work alongside ours. We met the deadline with 99.6 percent purity and a five-fold increase in the yield. It was a great experience, and the relationship and the communication were vital to making it a success.

THERE ARE CUSTOMERS WHO STILL PREFER TO WORK WITH CMOs THAT ARE A ONE-STOP SHOP. DO YOU PREFER THAT MODEL OR WORKING WITH CMOs THAT HAVE DIFFERENTIATORS TAILORED TOWARDS A SPECIFIC TYPE OF CHEMISTRY?

Alonso-Caplen: That’s a good question, and the answer is, it depends. For example, if I were sourcing for antibody drug conjugates (ADCs), a toxic material, having a supply chain that is fragmented will make it more difficult, especially if the drug substance is in the U.S. and the drug product is in Europe. In that case, I would prefer to go to a one-stop shop.

On the other hand, if I were sourcing for monoclonal antibodies, it really doesn't matter because we would not have the same supply chain concerns. We have CMOs and contract testing labs that are strong in that area. We have established platform methods with several companies, so it makes it much easier to source the testing to one contractor and the production to another. If a CMO were strong in one particular field, say conjugation, then by all means we would prefer to go with that CMO because they have seen a lot of these processes and we can actually learn from them.

Hoffmann: I think this is another situation that can be tied back to the project manager. If you have a one-stop shop that has a single project manager, that individual can follow your project all the way through the process, and there is only one person that you have to talk to at every step. That person will be responsible for managing the logistics of moving your project through the different production stages.

If you have several suppliers, each performing a different stage, you will need the resources to manage the entire process. It’s not impossible, but there are more logistics involved, and you have to make sure you have the manpower and resources to handle it.

DO YOU HAVE ANY ADVICE ON HOW TO MANAGE THE LONG CYCLE TIMES BETWEEN WHEN A CONTRACT IS SIGNED AND WHEN A PRODUCT MOVES INTO COMMERCIAL PRODUCTION?

Guiles: The best way to handle that is to think ahead and ask a lot of questions during your initial discussions in the RFP phase. Ask the CMO about capacity and any possibility of having to change facilities. If moving from Phase 2b to Phase 3 means moving into another facility, you would want to know that up front.

Novak: That is a good point, and it’s a situation that is sometimes unavoidable. Changes will occur when moving from Phase 2b to Phase 3. Suddenly, the project and the commercial capacity that the CMO signed up for have changed for the good of the owner.

But for the CMO, all of a sudden there is a realization that the equipment in-house will not be sufficient to produce the volume the customer is now requesting. In order to do it, there will have to be a large investment. We all know how tough it is on the CMO side to go to the board of directors and say, "Hey, by the way, I need $12 million for another fluid bed dryer." Realizing you suddenly need three times the quantity originally requested is definitely a challenge, but if your relationship is a true strategic partnership, then you should be able to sit down and work things out.

Hoffmann: Here again communication is a key component. There should be a collaborative process in place as your project moves through the different stages. As soon as you know there will be changes, let the CMO know. None of this happens in a vacuum. You have an idea as you move through the different phases of the clinic that your demand might be bigger, and your dose different, than what you originally thought. Always give your CMO as much advance notice as possible. Worst case scenario, if it's not possible for the CMO to accommodate your changes, then go with a second source, which the FDA would prefer anyway.

HOW IMPORTANT ARE SITE VISITS?

Hoffmann: Site visits are extremely important. Without them I don’t think you can really get a sense of the true capabilities of a CMO. The visits allow you to see firsthand what their labs and other facilities look like. The visits also give you a chance to talk to the technical staff. This will help you to determine how knowledgeable they are and whether or not they are able to answer your questions. Go prepared with specific questions to ask. The business development people are generally very knowledgeable, but the technical staff will be able to tell you how they would approach any problems that arise.

WHAT ARE SOME OF THE METRICS YOU USE TO GAUGE THE SUCCESS OF THE RELATIONSHIP?

Alonso-Caplen: My quick answer would be cost and timelines. You will have a schedule, a GANT chart, right from the beginning, which both sides have agreed upon and signed. There are also costs that have been agreed upon. We will typically pay for milestones and deliverables. This illustrates the difference between trying to get something done internally versus externally. Internally, getting something done can be like pulling teeth. But externally, if you don't deliver, we don't pay.

Hoffmann: Those are both important metrics. Once you get past those, I always try to think about how much time my team has to spend managing the project. If the sponsor/CMO relationship is going well, you should find yourself spending less and less time managing the project. It's a very easy and definitive metric. Just keep track of how much time you're spending on it.

Heidi Hoffman

Novak: My three favorite metrics are related to quality: on time, in full, and right the first time. I also like to look at deviations and CAPA closures. I recommend building a score card with all of the metrics on it and reviewing it monthly. Then quarterly, I recommend having a face-to-face business meeting with all team members from both sides to review the quarterly business metrics or your timeline.

DO YOU HAVE ANY ADVICE FOR DEALING WITH BAD CONTRACT TERMS THAT YOU INHERIT WHEN JOINING A COMPANY?

Lee: That's a tough one. I have seen agreements that will not even let you get a secondary supplier. That is risky, and I have seen companies get burned by it. When you select a CMO, you need a plan B as well as a backup. Many small pharma companies probably cannot afford to have two CMOs, but you really need to do what you have to in order to have a second supplier.

Novak: When I first joined Pernix, I had six of those contracts. One of the first things I did was to try and redo all of them. I sat down with the CEO of each company and went over our strategy. I told them I needed more flexibility, and if they couldn’t provide it, I would move the business. It might take me a year or two, but eventually I would do it. Four of the CMOs worked with me, but two of them refused to budge.

Eventually I did move the business, and those are two companies I will not work with again. As much as you want to retain all of those relationships, in some cases you are just not able to do so.