The CMO/Client Connection: What Makes It Work?

By Eric Langer, president and managing partner, BioPlan Associates, Inc.

Successful CMO relationships require hard work. To make it work, biomanufacturers and their service suppliers have developed processes to support their outsourcing and project management practices. But, they are not always successful. In our 8th Annual Report and Survey of Biopharmaceutical Manufacturing, we found this year that as productivity and performance factors become more critical, the relationships between CMOs and their clients are taking on greater importance. Evaluating and managing the connection is increasingly becoming a priority. The increasing requirements for productivity, process, and quality, and the global economy have heightened emphasis on risk management and cost containment. In this climate, partners who are sensitive to each other’s priorities stand the best chance of succeeding in the long term.

What Biomanufacturers Want from CMOs

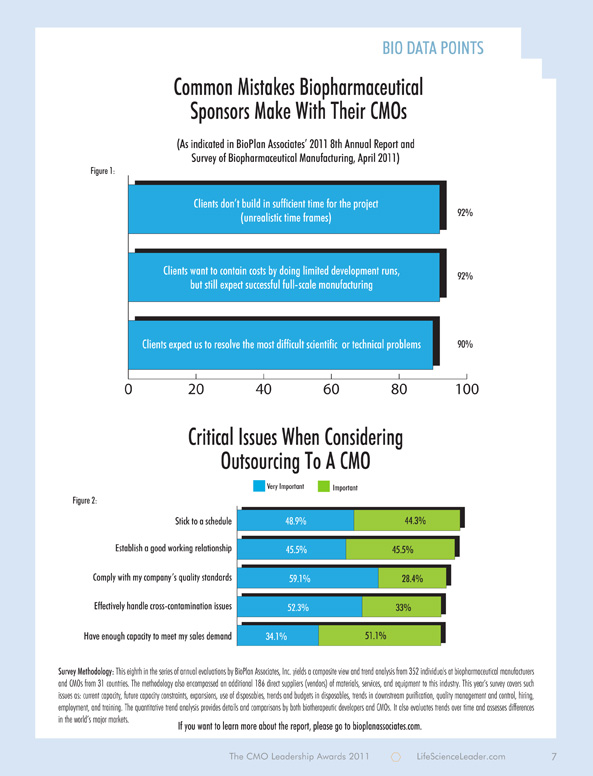

Biomanufacturers agree that some very specific criteria apply from the initial vetting process of a CMO through selection and performance evaluation. From our study, we identified which capabilities of a CMO the majority of biopharma executives rank highly. These include the following:

- comply with my company’s quality standards (59.1% indicating factor “Very important”)

- protect intellectual property (56.8%)

- effectively handle cross-contamination issues (52.3%)

- stick to a schedule (48.9%)

- establish a good working relationship (45.5%).

Significant Changes In The CMO Relationships

We also have tracked the changes over time regarding how important clients/sponsors considered certain factors when selecting a CMO. For instance, the largest increase during the past five years pertained to the importance of CMOs handling cross-contamination issues. During that time period, 32% more respondents identified cross-contamination issues as “Very Important” or “Important.” The second largest increase was “protect intellectual property,” which rose by 26.7%.

CMOs’ Problems With Clients

In the study, we considered the relationship issues from the CMO’s perspective, as well. This year we identified 11 critical issues that CMOs (i.e. contractors) find are the most common mistakes made by their clients (i.e. biomanufacturers). This is important to quantify as both sides work harder to improve their working relationships.

Two problems tied for the most critical factor (both scored 92% when adding the scores for the “Very Common” and “Somewhat Common”). First was “Clients don’t build in sufficient time for the projects (unrealistic time frames).” This factor grew significantly since last year, when only 82% indicated it as a common problem, and only 46% indicated it was a “Very Common” problem. The other first-place factor was “Clients want to contain cost by doing limited development runs, but still expect successful full-scale manufacturing.” Last year, 79% felt this issue was “Very Common” or “Somewhat Common.” Following these two first-place finishers were “Clients expect us to resolve the most difficult scientific or technical problems” and “Clients don’t plan their tech transfer process.” Close on their heels were communication problems and client lack of understanding of the variability in process development.

Part of the problem is that client expectations may be too high, especially in the current economic situation. Today, clients are looking to lower risk and are after the best service for the least price — to be completed in unrealistic time frames. It may be up to the CMO to help its clients establish more rational expectations.

To improve the relationship, CMOs are likely going to need to educate their clients regarding a number of misperceptions. These include GMP manufacturing costs, the need for more realistic timelines, better documentation approval review processes, and a better understanding of the time involved in process development work prior to the GMP manufacturing. In some cases, CMOs report they are pushed into GMP manufacturing, which can result in doing process development work at scale, which can be costly and lead to tense relationships.

A recurring problem cited by CMOs is that clients tend to want to limit development and engineering runs to save costs. This can end up hurting production runs because problems have not been worked out.

The Need For Strong Communication

Maintaining good client-vendor relationships is increasingly critical as the technical complexity of outsourcing increases. A root cause of many of the problems cited above is poor communication. This creates the persistent problems in “working relationship” issues that show up every year in this study. Nonetheless, with greater experience and better communication processes, we are likely to see a more collaborative vendor-client environment in the future.