ABOUT CYTIVA

With a rich heritage dating back hundreds of years, Cytiva brings a wealth of technical expertise and talent, a broad and deep portfolio, and exceptional service help researchers and biopharma advance therapeutics at every stage from discovery to delivery.

We supply the tools and support our customers need to work better, faster, and safer, leading to the delivery of transformative medicines to patients. Our combined portfolio includes well-recognized names such as Allegro™, Supor™, iCELLis™, and Kleenpak™, in addition to ÄKTA™, Amersham™, Biacore™, FlexFactory™, HyClone™, MabSelect™, Sefia™, Whatman™, and Xcellerex™. Visit cytiva.com to learn more.

PRODUCT VIDEOS

FEATURED PRODUCTS

-

Gene therapies hold immense potential to provide long-lasting treatments for a wide range of diseases. At Cytiva, we offer GMP-compliant, end-to-end manufacturing solutions designed to support the development and commercialization of advanced medicines across multiple modalities – including AAV, adenovirus (AV), lentivirus (LV), plasmid DNA (pDNA) and exosomes. Our dependable suite of technologies and expertise ensures scalability, quality, and regulatory confidence at every stage of your journey.

-

Research Use Only (RUO) lipid nanoparticle (LNP) reagents to deliver RNA into hematopoietic stem cells (HSCs) for cell and gene therapy applications.

-

Off-the-shelf, research use only lipid nanoparticle (LNP) reagents to deliver RNA into T-cells.

-

Bring confidence to filtration with an automated single‑use filtration system for pilot‑ and small‑scale manufacturing. This system is intended for crossflow filtration applications in both upstream and downstream workflows.

-

Explore a variety of cell lines, high-performance cell culture media, and single-use bioreactors to suit your process needs for any cell type.

-

Explore scalable and flexible single-use solutions from design to delivery that can help you overcome challenges throughout adeno-associated virus (AAV) manufacturing workflow.

-

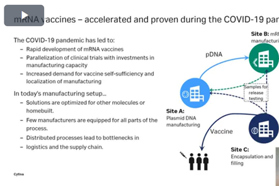

Learn about a scalable, single-use platform with built-in automation and regulatory compliance that enables standardized manufacturing workflows for mRNA-LNP drug product production.

-

The NanoAssemblr® commercial formulation system is an automated, single-use system for the clinical and commercial production of lipid nanoparticles (LNPs) under cGMP conditions. Designed for efficient changeover and robust manufacturing processes, the system enables operational flexibility and standardized manufacturing of genomic medicines.

-

Discover a one-stop-shop for LNP technologies that provides access to expertise in formulation and analytics for successful outcomes for payload and target applications. Explore end-to-end biopharma services and systems.

-

Designed for small-scale manufacturing, this single-use liquid chromatography system offers the performance and documentation required for a GMP-regulated environment.

-

Learn about coated magnetic particles that easily isolate and extract mRNA from a variety of sources and enable you to perform RT-PCR cDNA library construction, affinity purification, and more.

-

Synthesize oligonucleotides at scales of 10–100 mmol for early to mid-phase clinical trials or for diagnostic kits.

-

Looking for a user-friendly and compact oligonucleotide synthesizer with a large scale range? Discover a pilot-scale system that will take your drug through clinical development.

-

Explore systems for automated oligonucleotide synthesis, offered at a range of scales to support easy process development, optimization, scale up and transfer. Find the system that matches your needs.

-

The rise in approved oligo therapeutics has led to increased pressure on oligo manufacturers. Learn about modern chromatography resins, how they can help increase productivity in manufacturing, and more.

-

Discover the platform for oligonucleotide development and scale-up that is the result of 30 years of collaboration with leading oligonucleotide pharma. Explore this solution's benefits, specifications, and more.

-

OligoProcess covers a range of 10 to 1800 mmol and is suitable for quantities required in clinical phases and commercial production.

-

By combining disruptive technology platforms with unparalleled genomic medicine development expertise, we're positioned to accelerate the development of LNP formulations and drug products.

-

Ignite simplifies the transition into clinical programs by incorporating these fundamental process steps for scale up in the earliest stages of pre-clinical development.

-

GenVoy-ILM™ T Cell Kit for mRNA, Ignite is an lipid nanoparticle (LNP) reagent mix optimized for the delivery of messenger RNA (mRNA) or Cas9 mRNA/sgRNA into activated human primary T cells.

BROCHURES

- A Comprehensive Upstream Platform For Gene Therapy Applications

- AAV Manufacturing Workflow

- Single-Use System For Clinical And Commercial Production Of LNPs

- Services For Advancing mRNA-LNPs From Bench To Clinic

- A Disruptive Technology Accelerating Drug Development

- GenVoy-ILM™ T Cell Kit For mRNA, Ignite™

- A Next-Generation Technology For The Power To Scale

- T Cell Kit For mRNA On NanoAssemblr Spark

- NanoAssemblr® GMP System: Power To Commercialize

- GenVoy-ILM™: Power To Explore

- NanoAssemblr® Spark™: Freedom To Discover

WEBINARS AND PODCASTS

APPLICATION NOTES

- Oligonucleotide Purification And Synthesis

- Cell Culture Media Mixing In A Benchtop Single-Use Mixer

- Assessing Particle Generation In A Single-Use Mixing System

- A Transient Cell Line To Produce rAAV With Low-Level hcDNA Encapsidation

- How To Successfully Isolate Your T Cells

- Single‑Use Filtration System For Pilot‑ And Small‑Scale Manufacturing

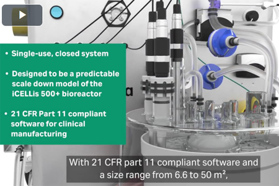

- Review Of Applications And Processes In Fixed-Bed Bioreactors

- Lentiviral Vector Production Using Single-Use Bioreactors

- Get Full Control Of Your T Cell Isolation

- Using Automated Spinoculation For CAR T Cell Lentiviral Transduction

CONTACT INFORMATION

Cytiva

100 Results Way

Marlborough, MA 08855-1327

UNITED STATES

Phone: 800-526-3593

FEATURED ARTICLES

-

Learn how buffer choice, gradient strategy, and pretreatment steps influence recovery, purity, and resolution when purifying a native RNA oligo, with analytical confirmation and practical guidance.

-

Explore how an optimized solid‑support design enables higher synthesis scales, steadier pressures, and lower solvent use while preserving yield and purity across diverse oligonucleotide lengths.

-

Lipid nanoparticles enable precise, non-viral gene editing in T cells to achieve high HDR efficiency and viability in scalable workflows. Explore how this approach overcomes viral vector limitations.

-

AAV vectors hold promise for gene therapy, but removing product-related impurities remains a challenge. Learn how cell line development and process optimization are advancing rAAV production.

-

Cell culture media isn’t one-size-fits-all. Learn how media composition, customization, and analytics can dramatically improve cell growth, productivity, and product quality for complex processes.

-

Scalable rAAV production is achievable with a transient cell line and optimized bioreactor setup, delivering high titers and reduced impurities, now validated at 200 L scale for commercial readiness.

-

Fixed-bed bioreactors simplify the scale-up of viral vector production. Discover a system that bridges development and manufacturing with data confirming consistent performance across scales.

-

Explore how powder media and sterile fluid handling can reduce contamination risk and improve efficiency in viral vector production, especially for HEK293-based AAV workflows.

-

Explore a high-yield, scalable process for hMSC-derived exosome production using fixed-bed bioreactors, with strong performance in purity, recovery, and biological activity.

-

Get a clear view of oligonucleotide development from synthesis to purification and filtration with practical insights to help you streamline workflows and stay ahead in the fight against disease.